Conformal Cooling

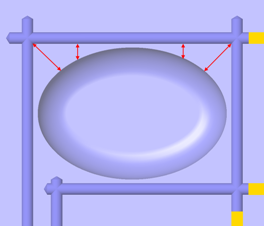

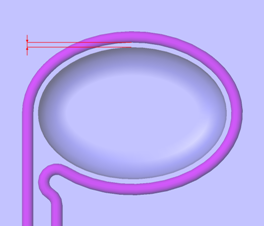

Conformal Cooling = cooling circuit designed so that the shortest possible distance from the wall molding replicates the surface.

Technology DMLS (Direct Metal Laser Sintering) is applied to new molds of efficient cooling system - Conformal Cooling. Conformal Cooling can be applied to existing molds.

Conformal Cooling can be treated with anti-corrosion coating.

| Drilled cooling circuit | Conformal Cooling | |

|

|

Conformal Cooling - benefits

- shortening the cooling cycle time up to 50%

- reduce warping

- homogeneous heat transfer from the mold cavity

- optimization of the cooling circuit as part

- absolute freedom in the design of the cooling circuit

Technical Specification - Conformal Cooling

- technology: DMLS - Direct Metal Laser Sintering

- machine: EOSINT M270

- workspace: 250x250x215 mm

- imput format 3D data: *.stl

- material: MS1 - 1.2709

- guaranteed minimum cooling channel diameter: 3 mm (no guarantee less)

- guaranteed minimum distance between the channel wall and the wall of the cavity: 3 mm (no guarantee less)

- Conformal Cooling can be treated with anti-corrosion coating

- heat treatment up to 54 HRC

- recommended allowance for subsequent machining (CNC, EDM, polishing, etc.)

- can be connected to existing classically drilled cooling circuit

Conformal Cooling

If interested in Conformal Cooling, please contact us through this form.